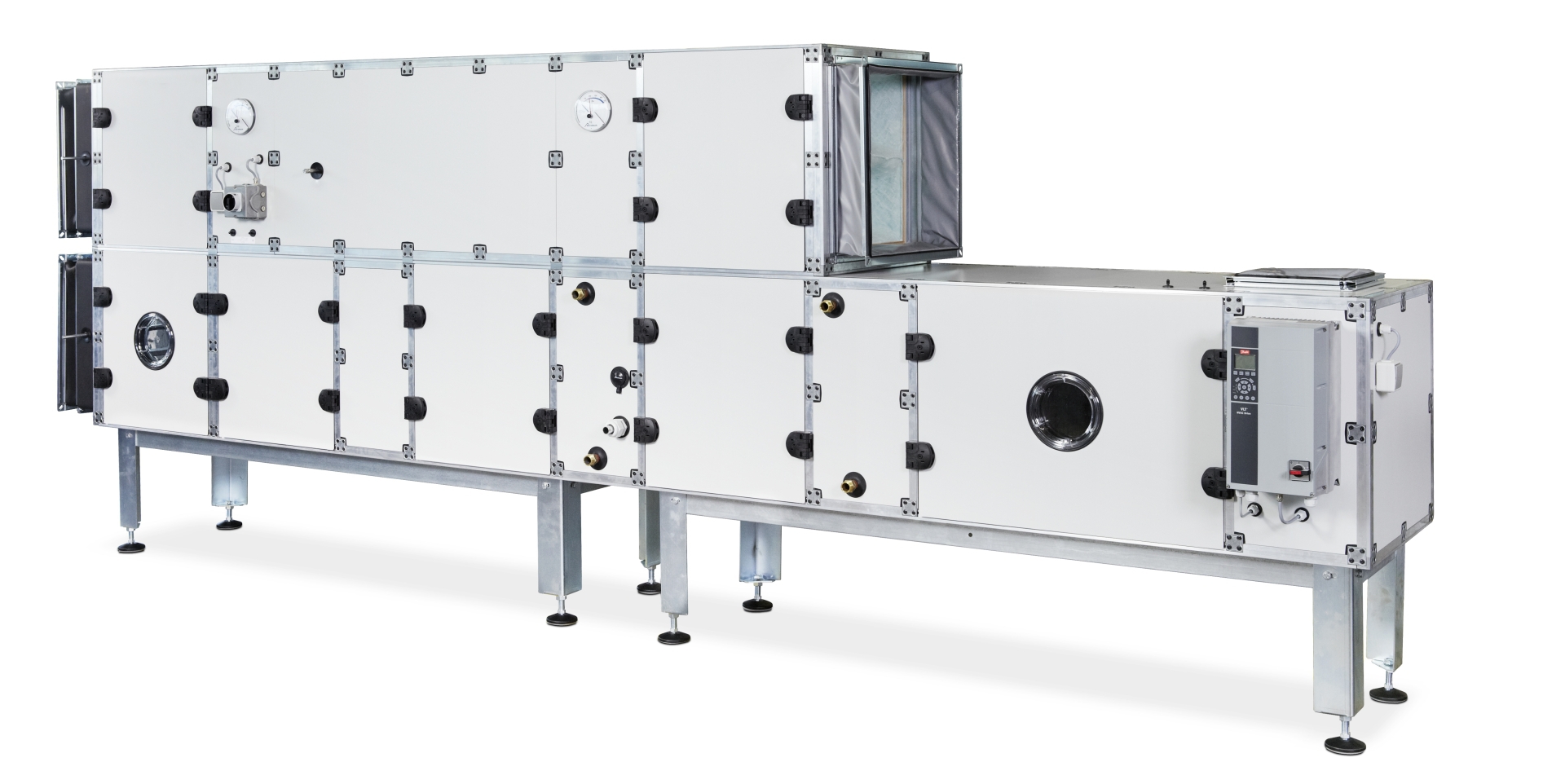

Complete thermal separation

Even when significant temperature differences are involved, no condensation forms on the housing as there are no thermal bridges (as defined in EN 1886 Thermal bridging factor TB2 / TB1). The 35 or 70 mm thick sandwich panels, filled with either polyurethane foam or silicone-free mineral wool, also guarantee a low heat transfer factor (as defined in EN 1886 Heat transfer coefficient T2 /T1).

Modular construction

The housing construction is very versatile due to the modular design. In combination with standardised components it provides endless design possibilities. We have retained our tried and tested 620 x 620 mm module grid and have therefore kept all the benefits of the frameless housing.

Flexible and robust

Newly developed doors without thresholds can open in either direction or be removed altogether. This means that we can now offer you even greater flexibility, together with maximum surface stability and torsional

stiffness. The frameless housing can also withstand heavy point loads and can be walked on both inside and outside (as defined in EN 1886 housing class D1).

Hygienic and safe

All internal surfaces are completely smooth – for optimal air flow and hygienic areas that are easy to clean. These are the best hygiene conditions under VDI 6022 and H 6020. We were awarded the highest level of classification for our perfectly matched filter units (Filterbypass leakage F9).

Easy installation

We can supply the entire unit in one piece, or deliver it in sections or knocked down for straightforward on-site assembly.

Thermal bridges at the housing

TB2 / TB1

Temperature readings taken at 120 points on all relevant parts of the housing confirm that the average outside temperature conforms to the standard value and each individual measurement point achieves the value for TB2 (35 mm) and TB1 (70 mm)

Heat losses through the housing wall T2 / T1

To determine the heat loss through the housing wall, the temperature difference between the housing interior and exterior was established under standard conditions. From the heating output emitted in the housing, a heat transfer coefficient of 0.9 W/m²K was established.

Air tightness of housing L1

The flow rate of air leakage from the housing was ascertained for two different test pressures (-400 Pa 0.05 l/sm² and +700 Pa 0.08 l/sm²). Here again, the highest possible result described by the standard was achieved.

Deflection of housing D1

At pressure conditions between -2500 Pa

and +2500 Pa, only a minimal deflection

occurs to the housing (no permanent deformation). modul a excelled on test with 1.2 mm/m deformation at +1000 Pa.